Specialty Filaments

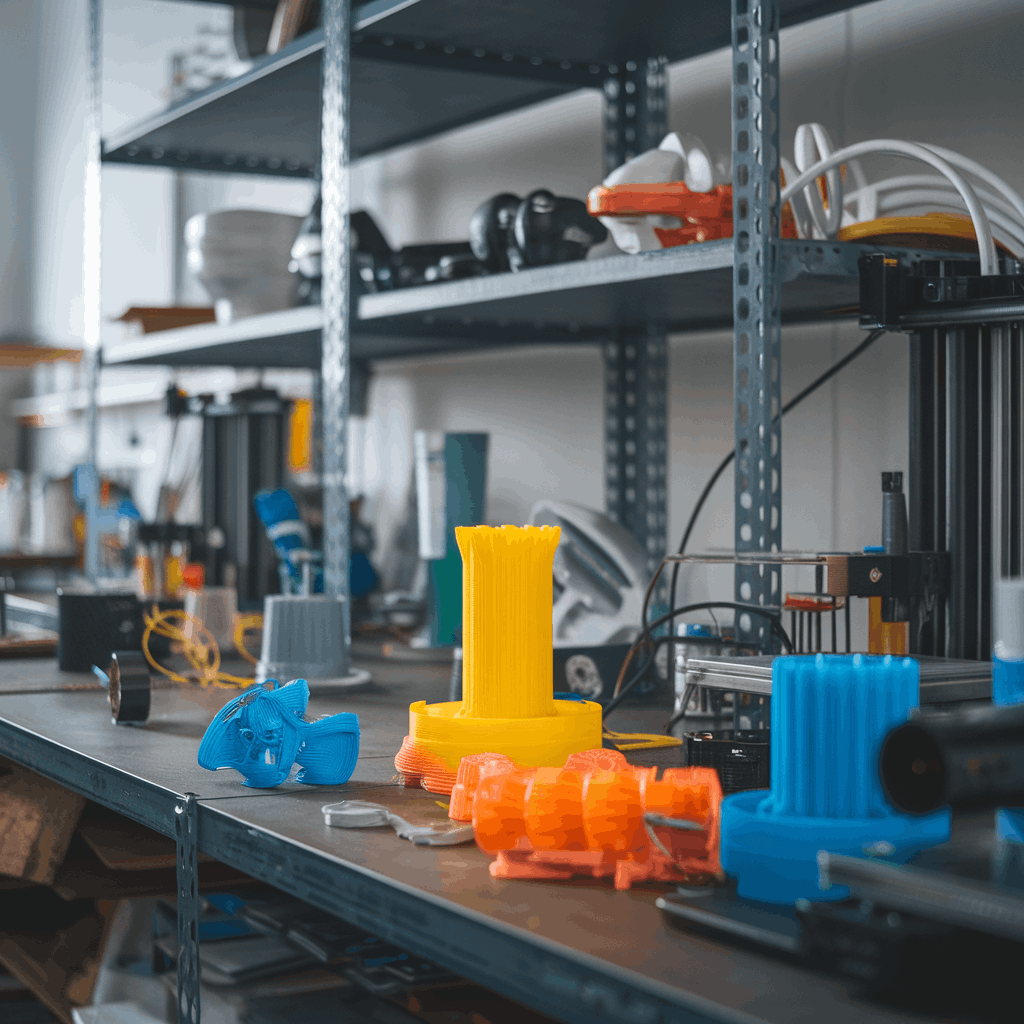

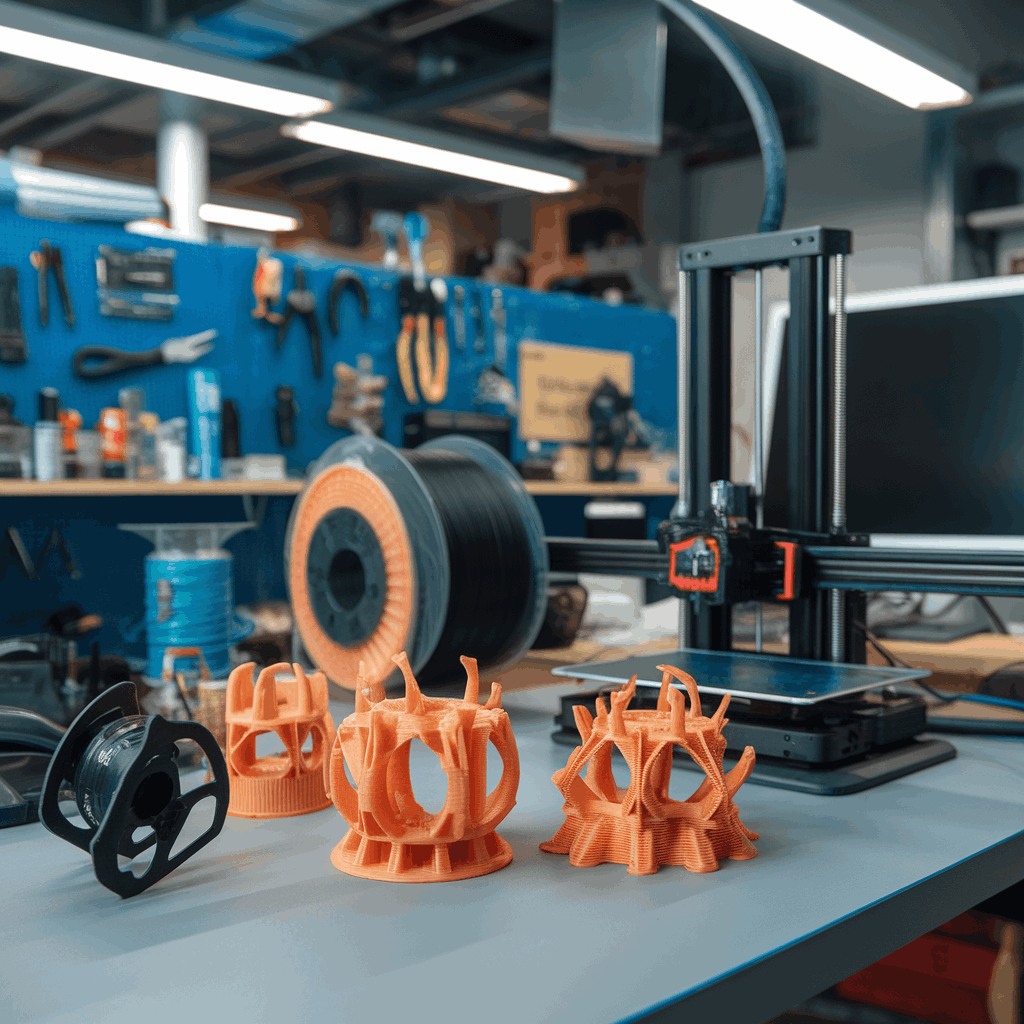

Carbon‑fiber reinforced, ESD‑safe, high‑temp nylon and PETG blends. Tight ovality, moisture‑controlled spooling, batch traceability.

- Diameter tolerances ≤ ±0.02 mm

- Spool sizes: 0.75–8 kg

- Custom color and additive packages

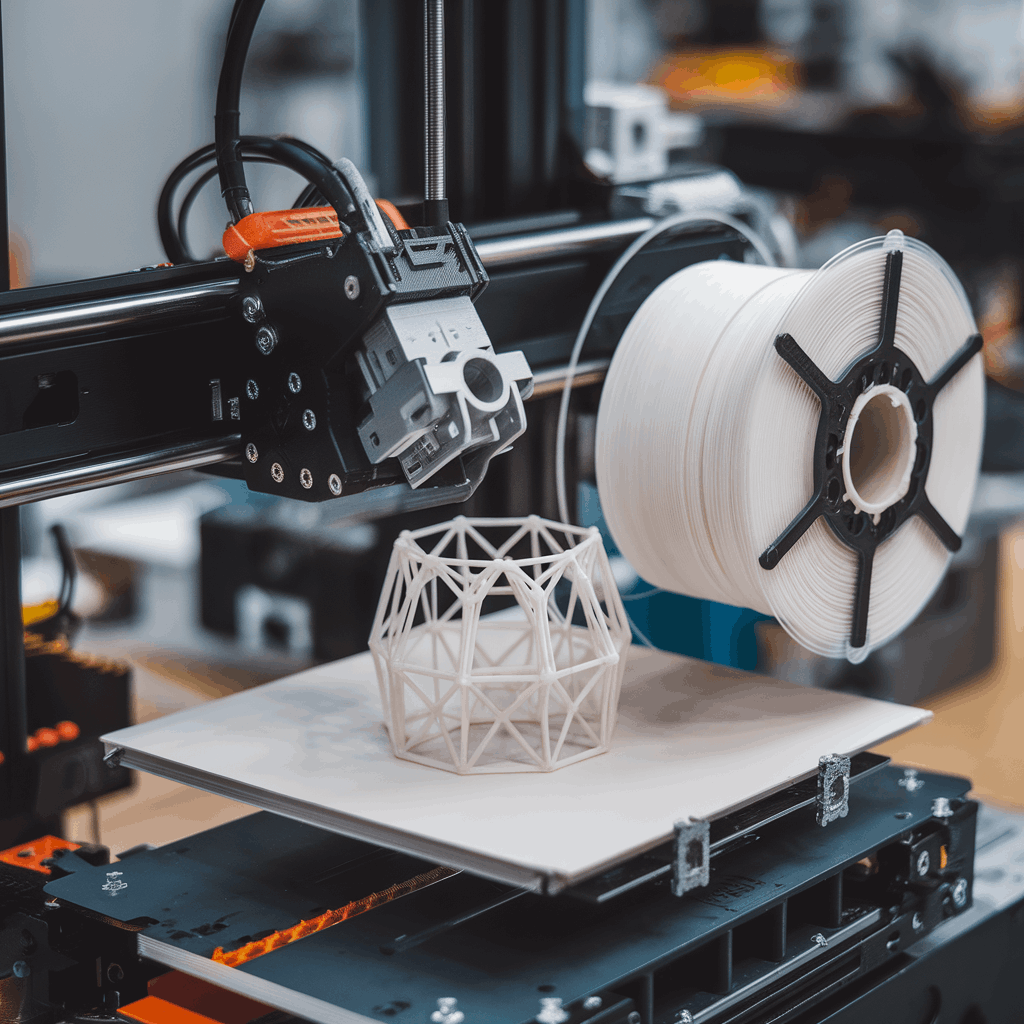

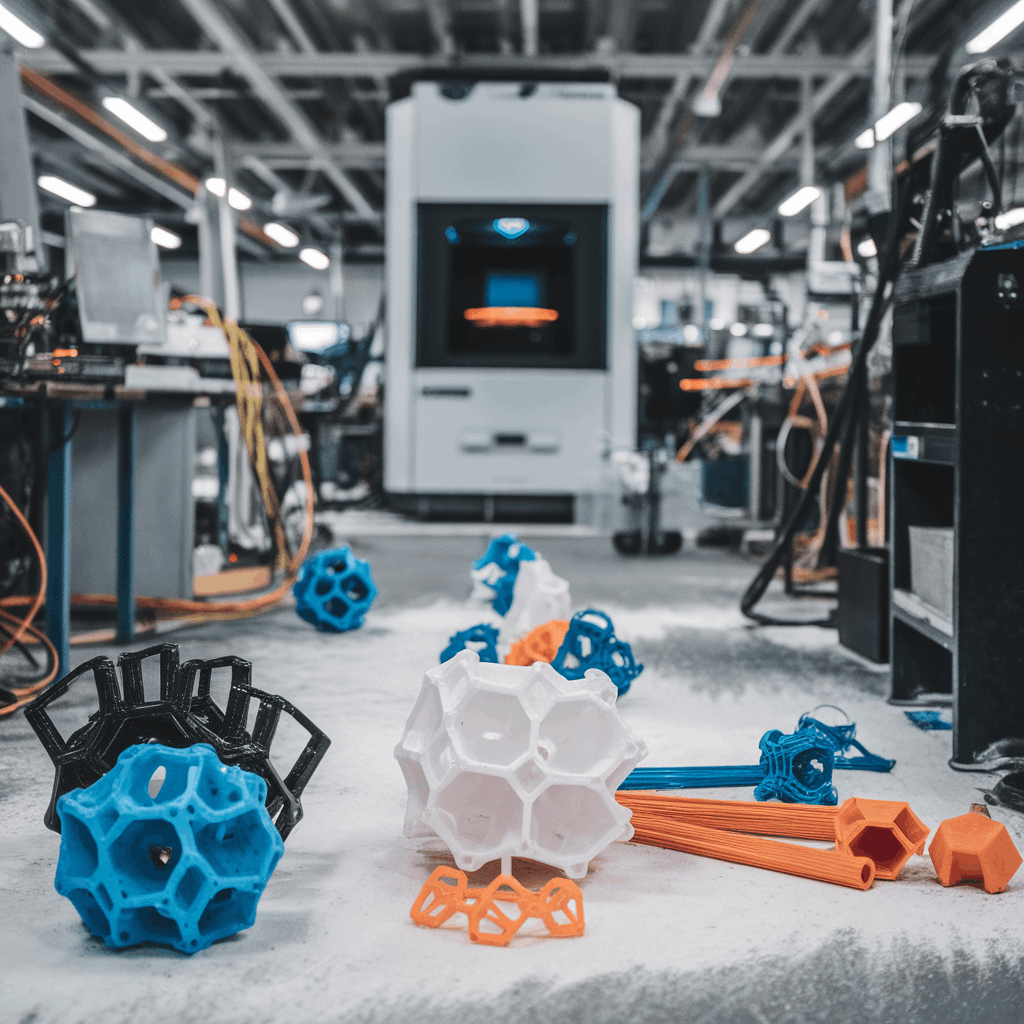

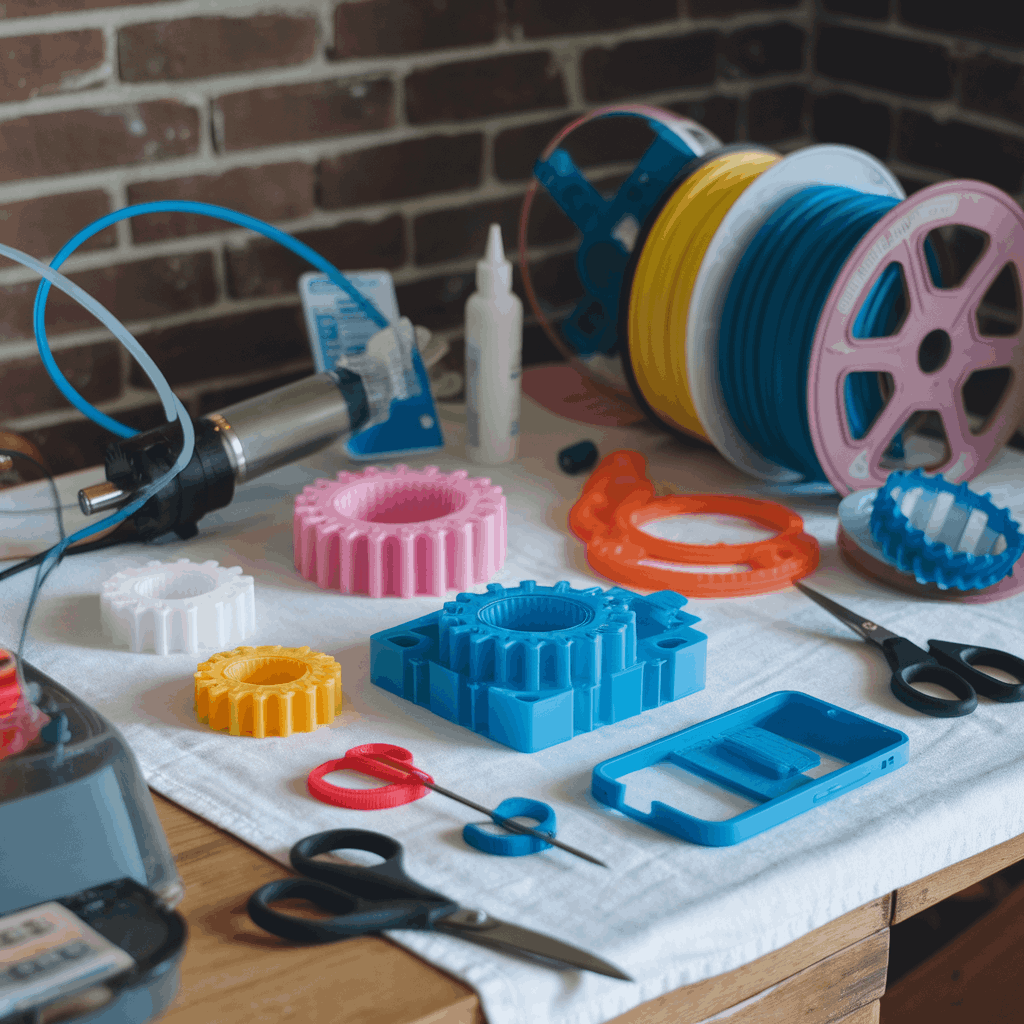

We manufacture components that keep your printers running: engineered supports, specialty filaments, and hardened nozzles designed for abrasive materials. Trusted by Malaysian manufacturers and regional labs.

Carbon‑fiber reinforced, ESD‑safe, high‑temp nylon and PETG blends. Tight ovality, moisture‑controlled spooling, batch traceability.

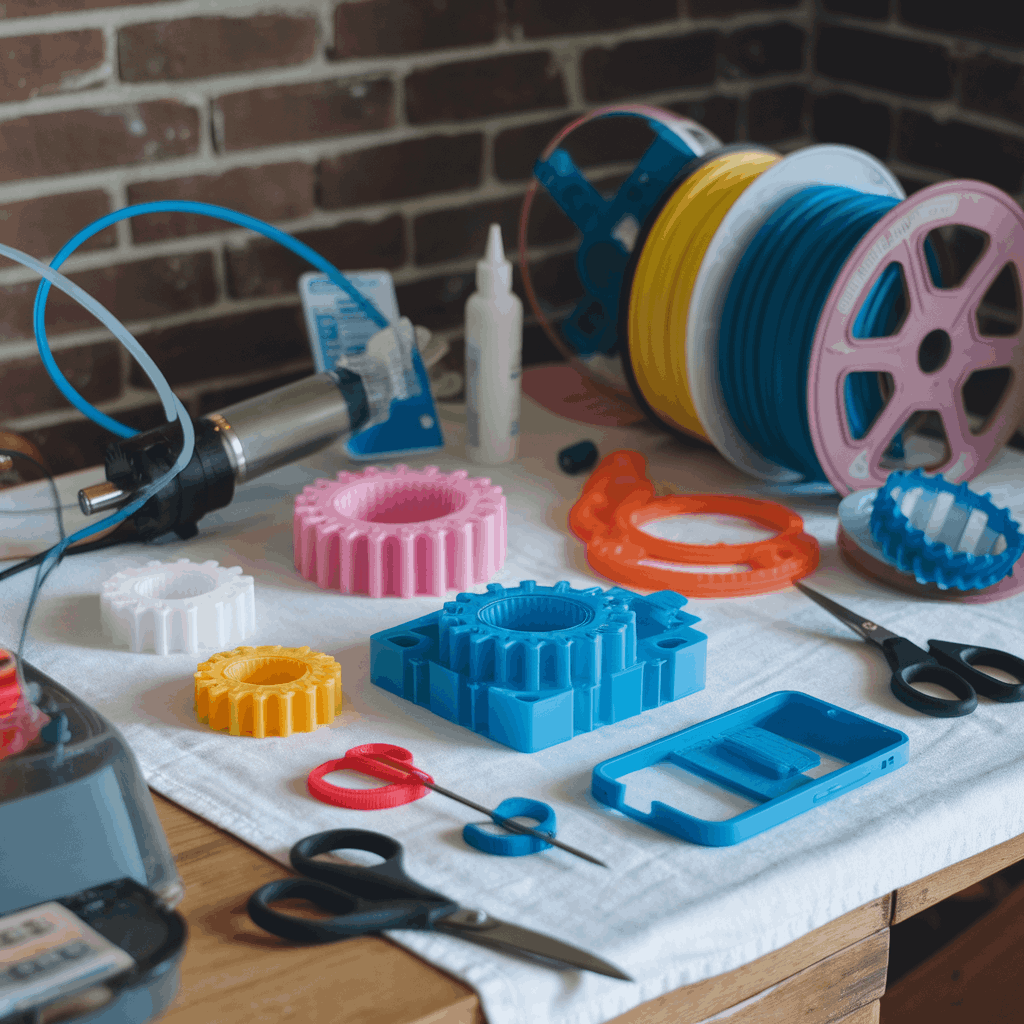

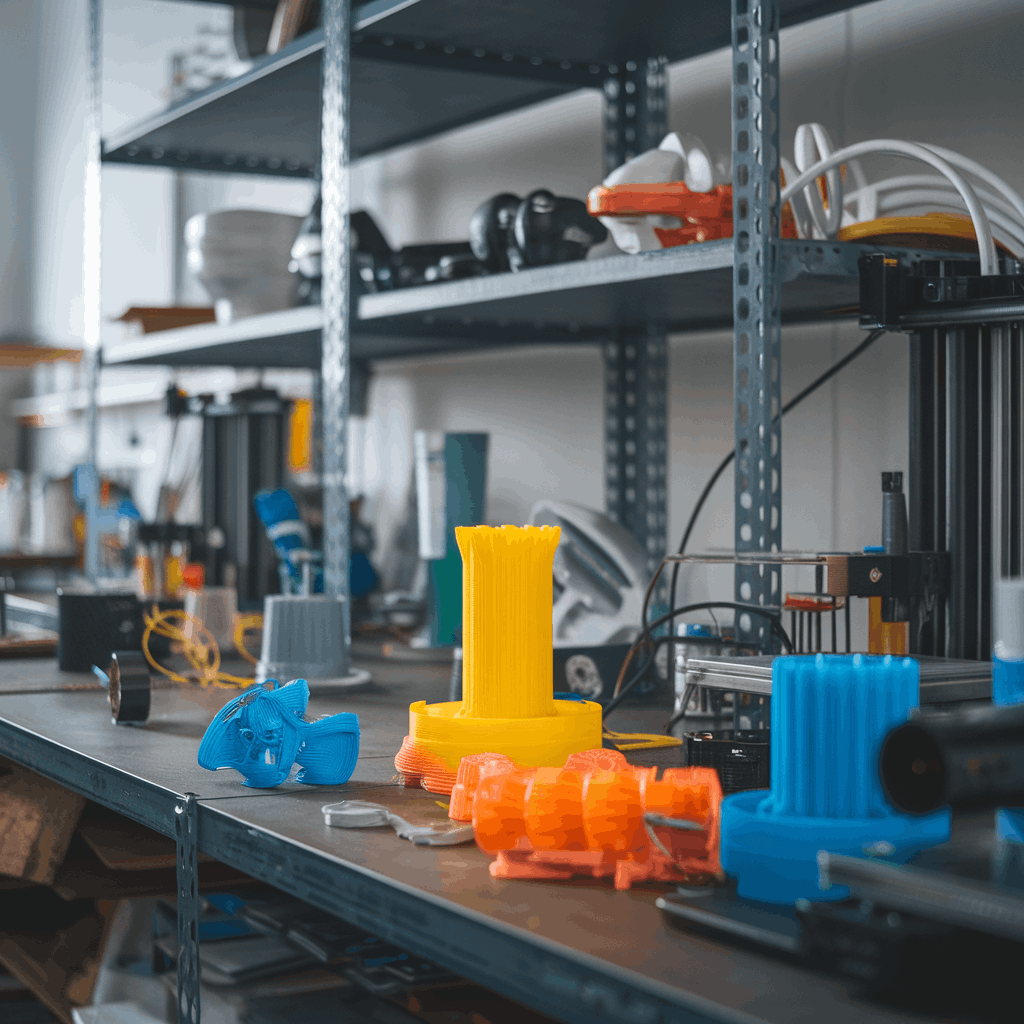

Wear‑resistant nozzles for abrasive filaments. Available in tool steel, ruby‑tipped, and nickel‑coated brass for consistent extrusion.

Breakaway and soluble support systems tuned for complex geometries. Clean separation and predictable dissolution times.

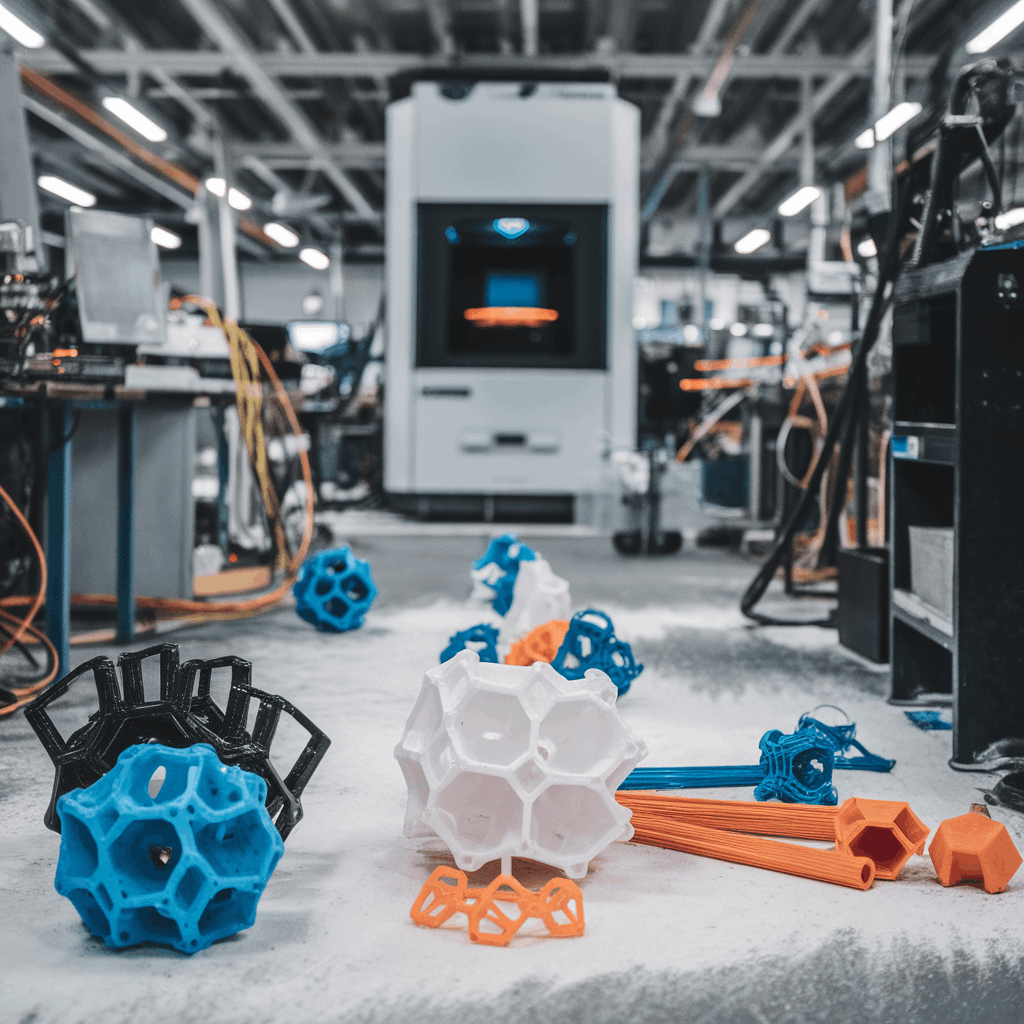

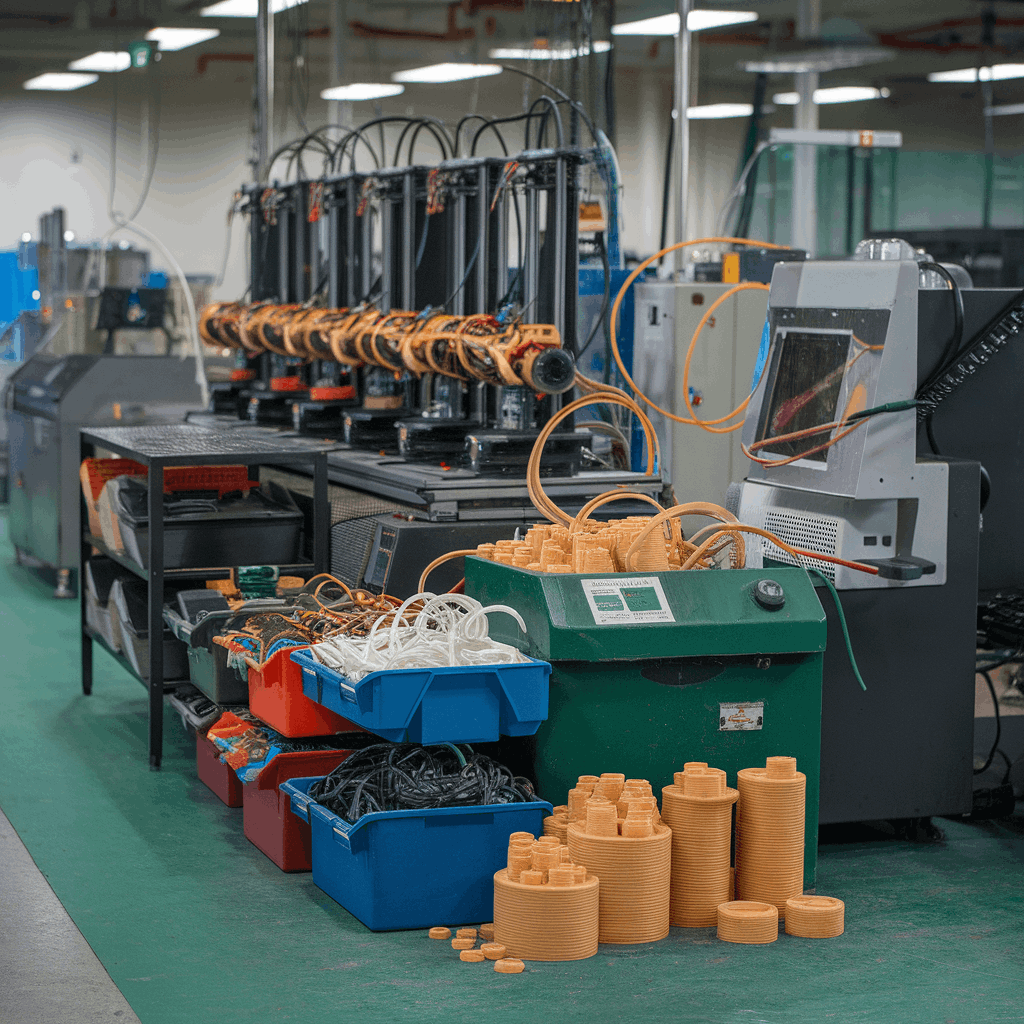

Our Petaling Jaya facility blends automated extrusion lines with in‑line laser measurement and post‑processing cells. We build for uptime: lean setups, quick changeovers, and statistical process control ensure repeatability across long runs.

Material selection is where reliability begins. We source engineering‑grade resins, stainless and tool steels, and specialty additives from audited suppliers. Our incoming QC and in‑process checks are documented and retained.

“We shaved 18% off print time while improving surface finish. LayerForge’s profiles and supports helped us stabilize production for a regional appliance line.” — Ops Manager, Selangor

ESD‑safe jigs, fixtures, and housing prototypes for rapid iteration.

Production aids that reduce changeover time on assembly lines.

Reliable consumables for teaching and research environments.

High‑temp materials for under‑hood prototypes and fixtures.

Learn more about additive manufacturing from Machine Design or explore 3D printing research on Nature.

Share your requirements and our applications team will respond within one business day. For urgent requests, call our line below.

Order hotline: +60 3-9212 5487

Email: contact@reviewiszf.org

Hours: Mon–Fri, 9:00–18:00 (MYT)

LayerForge Components Sdn. Bhd.

12 Jalan PJU 7/3, Mutiara Damansara,

47810 Petaling Jaya, Selangor, Malaysia